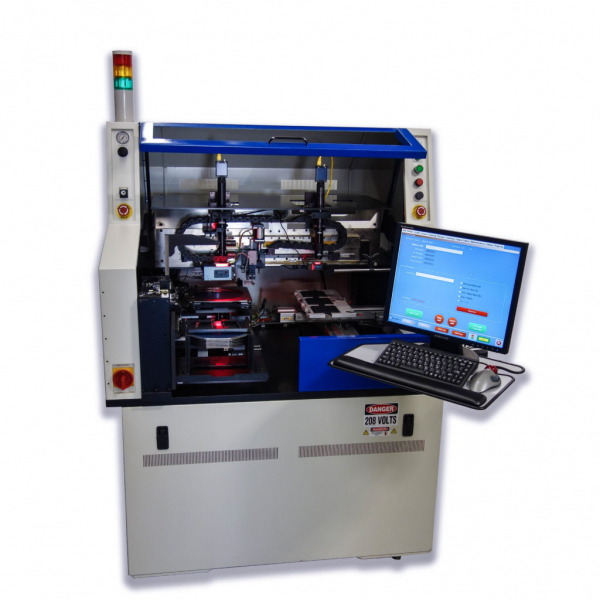

DTS-1 Wafer Die Sorter Equipment

Wafer packaging operations require dependable equipment to sort die from diced wafers by electrical data, visual inspection/AOI criteria, and other characteristics. The DTS-1 is a fully automated die-sorting system designed to meet your company's requirements for both speed and flexibility. Die sorter capabilities and features include, but are not limited to:

- Suitable for low- and medium-volume productions

- Ability to produce up to 6000 DPH throughput with +/- 15µm accuracy, depending on the product

- Runs on Windows 10 OS

- Small footprint of 1.2x0.97m

Syagrus Systems manufactures DTS-1 die sorter machines and other die sorter equipment for wafer packaging applications. We strive to solve any problem in most industries through silicon wafer backend processing and wafer sorter equipment manufacturing services. Contact us or request a quote today to learn more about how our DTS-1 die sorter equipment can benefit your application.

The DTS-1 is the Industry’s Most Flexible & Accurate Wafer Sorter Equipment

DTS-1 die sorter equipment utilizes a single head with an optional inverter to complete die transfer. For full technical specifications and optional configurations, download our free DTS-1 sorter system datasheet.

DTS-1 pick-and-place systems feature a single head to deliver accurate and repeatable performances in low- or medium-volume productions. For assistance selecting the best wafer sorter for your line, call 651-209-6515 to speak with a representative directly.

Input Formats

DTS-1 pick-and-place systems feature a single head to deliver accurate and repeatable performances in low- or medium-volume productions. For assistance selecting the best wafer sorter for your line, call 651-209-6515 to speak with a representative directly.

DTS-1 wafer sorter equipment features high flexibility on input. Manually load up to 200mm wafer frames or upgrade to the optional 300mm capabilities. Wafer frame conversion kits are included, and optional hoop ring or grip ring adapter plates are available.

- Die size from 0.15mm up to 45mm sq.

- Die thickness as low as 10µm

- Diced wafer, waffle pack, gel pack, grip rings, and JEDEC trays

- Bowl feeder

Output Formats

As with input, the output formats of DTS-1 die sorter machines feature high flexibility. Die sizes range from 0.15mm up to 45mm sq., including thicknesses as low as 12µm. Other capabilities are available:

- Invert or non-invert

- Wafers up to 300mm/12”

- Waffle pack, gel pack, tape and reel, grip ring, saw frame, and JEDEC trays

The DTS-1 can be outfitted with an optional tape and reel output with a tape width ranging from 8 to 44mm. This option includes a programmable tape index pitch, level wind supply reel, and an optional reject die removal and replacement system.

DTS-1 Die Sorter Equipment Vision Inspection Capabilities

Ensure quality wafers that function as designed with the DTS-1 wafer sorter. This equipment detects minimum defect sizes of 10µm for 12mm die and searches for a vast range of flaws, including:

- Surface defects

- Chipping and cracking

- Bumps

- Foreign material

- Laser marking defects

- And more!

Camera resolutions come standard at 640x480, with optional higher resolutions possible depending on your required defect size. Optical character recognition (OCR), Collet inspection, and topside or bottom-side inspection capabilities are also available. Additionally, the DTS-1 features OCR text or QR code recognition and mapping to innovate your production further.

Contact Syagrus Systems to Learn More About DTS-1 Wafer Sorter Equipment

Syagrus Systems focuses on creating solutions for problems and helping you transition from engineering projects to full production ramp-up. Contact us with questions or request a quote to start your order. A representative will be in touch to discuss timelines, pricing, and other details specific to your project.