Wafer Backgrinding Services | Silicon Wafer Thinning

Wafer backgrinding, or wafer thinning, is an essential semiconductor service designed to reduce wafer thickness to integrate and package circuits in smaller electronic devices. Syagrus Systems is an experienced provider of ISO 9001:2015 certified wafer grinding services. Our engineers can achieve your desired thickness and surface smoothness without damaging or compromising the strength of your silicon wafers. We use the 3M™ Wafer Support System to meet demands for extremely thin silicon wafers and dies used in complex applications. Whether you have one or several thousand silicon wafers that require thinning or back grinding, we have the right solution for your project.

Syagrus Systems can take your thin wafer all the way to a singulated die form through our comprehensive silicon wafer services. Contact us today to learn more about our abilities and wafer thinning processes. Request a quote to start your order.

Service Capabilities

Our capabilities include:

- Thin wafers from 4” to 8” diameter

- Backgrinding to target thickness of 0.025mm (0.001”)

- Single die, partial wafer, or bumped wafer backgrinding

- Thickness variance under 5 microns

Why Work With Syagrus Systems?

Advantages of working with Syagrus Systems include:

- Fast cycle times with same-day service available

- More cost-effective than chemical-mechanical alternatives

- Wide selection of grinding tapes

- Grind wheels that exceed the industry standard of 2000 grit

- Engineering staff at your disposal for engineering and prototype runs

- Safe, damage-resistant packaging to support thin wafer shipping

- ISO 9001:2015 certified

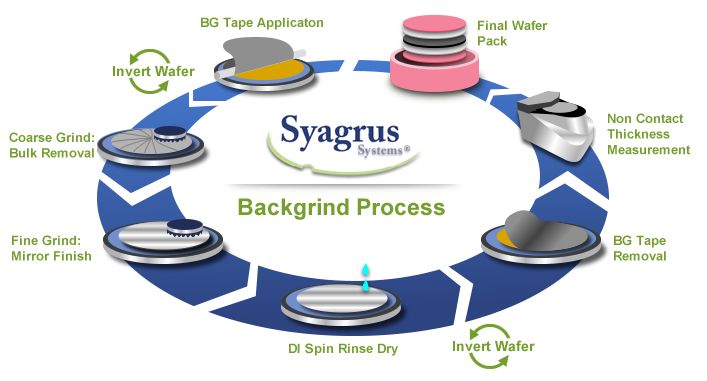

Expert Wafer Backgrinding Processes

Syagrus Systems utilizes a diamond-resin bonded grinding wheel to remove the silicon material from the back of a wafer. Our experienced specialists efficiently remove the bulk of substrate material on the wafer before the final finish grind, or polish. Deionized water is used to wash debris from the surface and prevent contamination.

All Syagrus Systems’ wafer backgrinding is performed in a class 10K cleanroom with critical thin wafer taping processes performed at a class 100 workstation. UV curable or standard adhesive backgrinding tape is temporarily applied to protect your silicon wafers from damage during wafer grinding.

Contact Syagrus Systems For Silicon Wafer Backgrinding Services

Syagrus Systems uses our state-of-the-art wafer back grinding processes to give you a leading edge over your competition. We always follow our strict in-house quality protocols, including visual inspections, while meeting your necessary requirements to ensure you only receive the best results.

Ready to learn more about how Syagrus Systems can meet your wafer backgrinding needs? Request a quote on wafer thinning and backgrind services or contact us for more information.